In its Electric Vehicle Market Forecast 2023, Investing News reports that globally there are more than 27 million electric vehicles on the road. Analysts expect that number to surpass 40 million by the end of the year. As the popularity of electric cars grows, so does curiosity, misinformation, and skepticism about the viability of the batteries that power them.

In the following post, the team at Financial Fuel Services unpacks three key challenges electric vehicle manufacturers and their adjacent industries face as they source, build, and recycle EV batteries. Read on to learn more.

1. Battery Weight

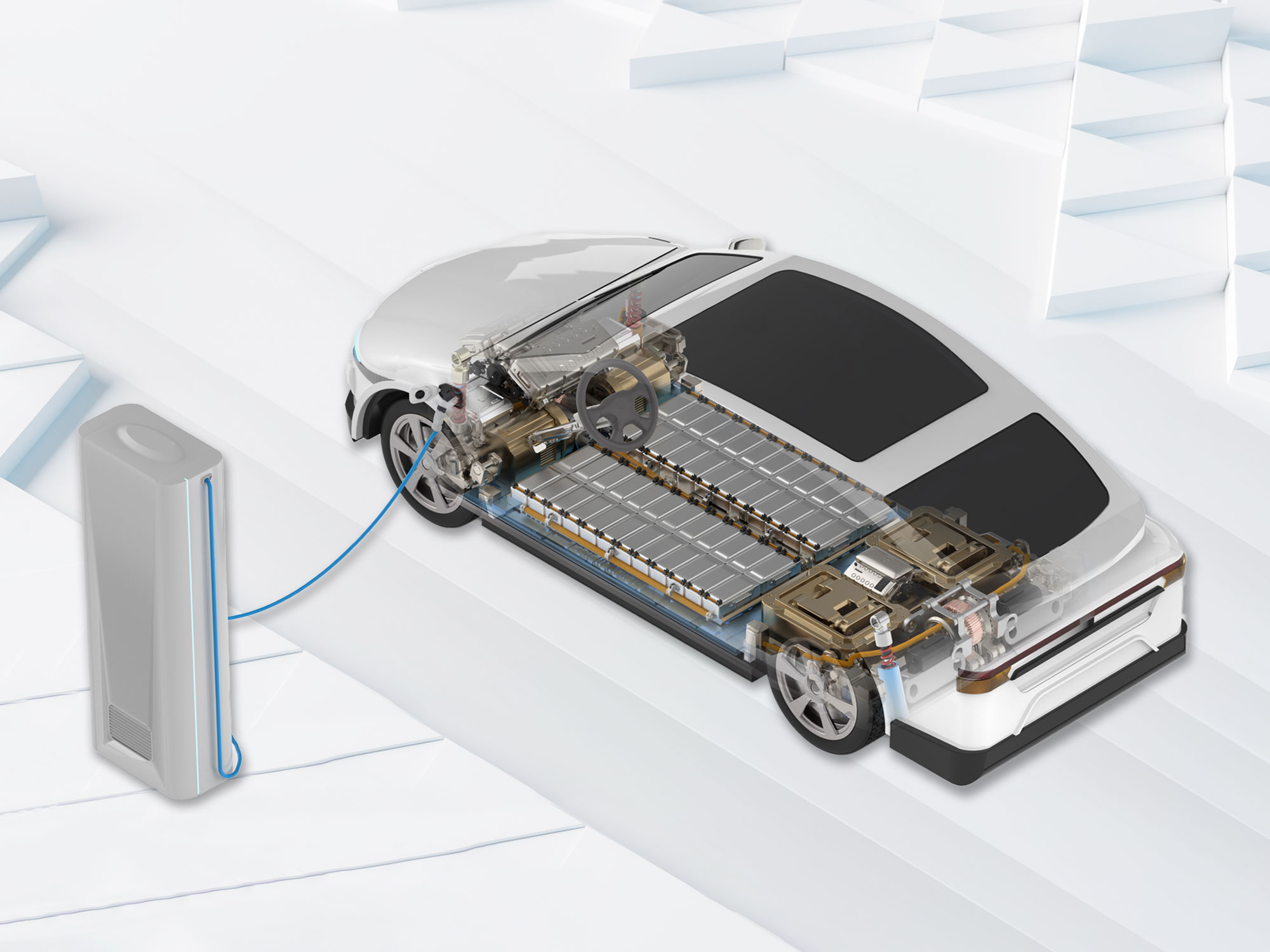

Thousands of small, interconnected cells form the lithium-ion battery pack that powers an electric car. Between two-thirds and three-quarters of the battery’s weight comes from those cells. Another quarter of the battery’s weight is from its components, such as cables and thermal management systems. The bigger the EV battery, the more energy storage capacity it has.

For example, a Tesla Model Y with a 330-mile range has a battery that weighs more than 1,700 lbs. A typical car battery weighs between 25 and 50 lbs. The heavier weight doesn’t necessarily translate to a lack of safety, primarily because EV manufacturers trade out steel and other heavy metals for lightweight materials when they build vehicle components.

2. Materials

Cobalt, lithium, manganese, and nickel are the precious metals found in most electric vehicle batteries. The battery of an electric passenger car will have just under 20 lbs of lithium, more than 30 lbs of cobalt, nearly 45 lbs of manganese, and 110 lbs of nickel.

Sourcing those metals has become increasingly difficult due to supply chain issues, some of which started during the pandemic and much of which worsened as the Russia-Ukraine war has continued. In the past year, electric vehicle manufacturers have been scrambling to find new sources of these four precious metals and mine them sustainably. If they cannot find new, reliable sources, the price of electric vehicles will stay high and potentially price out many consumers.

3. Recycling

The increased demand and tightening availability of EV battery materials have shifted the industry’s focus to how businesses can improve battery recycling. There is no single company that collects and disassembles batteries, making them available for purchase. Rather, it’s a hodgepodge of small businesses and nonprofits who are still trying to figure out how to scrap metals and build new batteries from recycled materials.

In a Benchmark Mineral Intelligence report cited by The New York Times, researchers estimated that scrap metal will account for nearly 80 percent of recyclable materials globally by 2025. They predict scrap will remain the go-to source of materials for EV batteries until the mid-2030s when used batteries will replace them.

Book Your Consultation with Financial Fuel Services Today

Don’t get blindsided by the ever-changing world of electric vehicles. Book a consultation with Financial Fuel Services today. Our team can walk you through the financial benefits of installing EV chargers at your franchise locations and guide you through the logistics.